Navigating the Green Transition of Fashion with technology

Deda Stealth at the front line to support brands' sustainability strategies

Viktoriia Shiriaeva, Presales Specialist of Deda Stealth

The

principles of the circular economy, from reusing to repairing and

recycling, represent the future of fashion (and beyond) and the most reliable

answer for the next generation's well-being. The circular economy, in

contrast with the linear model, is a system that aims to reduce waste and

trash by reintroducing materials and items back into the production cycle

at the end of their life span. The belief behind this model is that every item

is born to live multiple lives.

Why is it crucial?

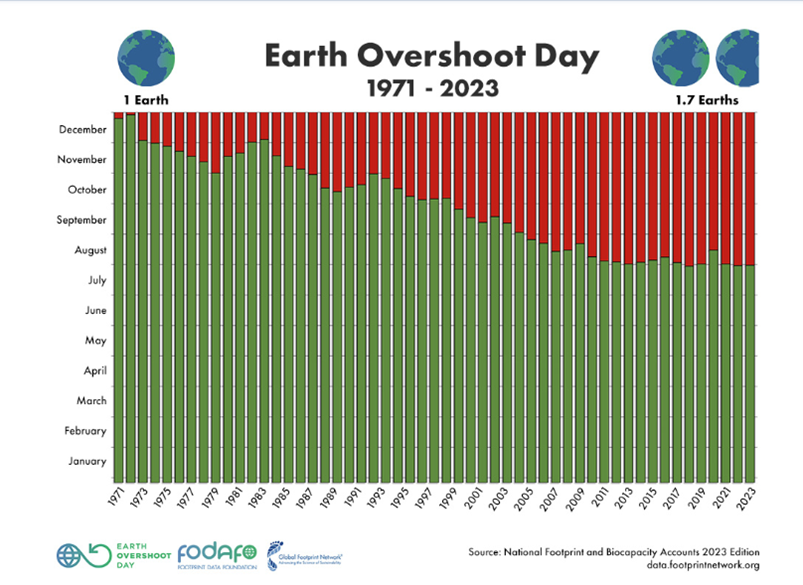

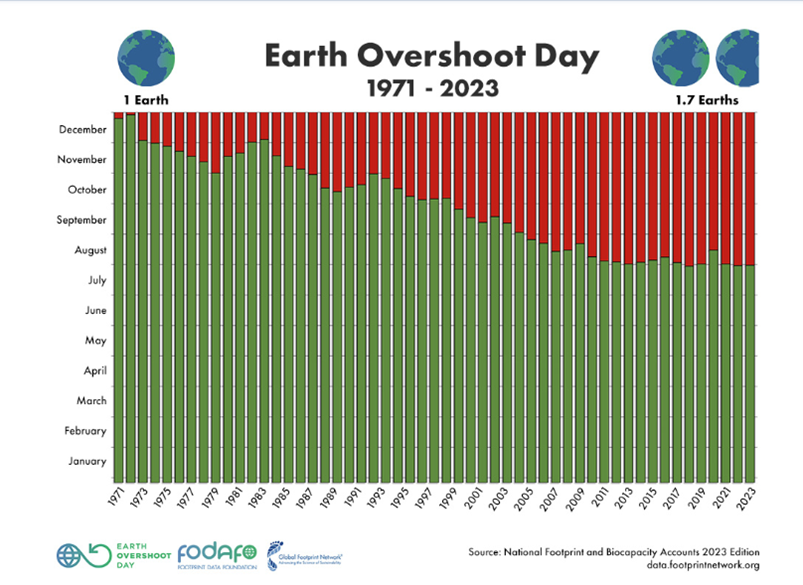

The chart

below shows the Overshoot Day i.e., the day of the year when the

consumption of all the resources produced by the planet is determined. This parameter has been recorded from the 1970s till 2023.

For 2023,

the earth overshoot day fell on August 2nd. Meaning

that on that date it is estimated that we ran out of the resources that our

planet can produce in one year, and therefore for the remaining time in 2023 we

would be "borrowing" resources from the following year, basically as

if we had one and a half planets instead of one. Earth overshoot day 2024

hasn't been announced yet, but the trend is disturbing.

Traceability and Transparency: the enablers of a circular economy

The

circular economy fits into this context as one of the possible solutions to

look at, and significant contributions are coming from governments

worldwide, especially in the fashion industry. Starting from January 2022, in

fact, the obligation to collect textile waste separately has been

introduced in Italy, which is a law that will come into effect by 2025 at the

European level as well. These initiatives aim to facilitate the reuse and

recycling of waste to slowly get to the point where waste is reduced to the

bare minimum. Other legislative and regulatory initiatives address the two

enabling factors for the circular economy: transparency and traceability.

Promulgated on 10 February

2020 and entering in force on 1 August of the following year, the AGEC anti-waste law (loi Anti-gaspillage pour une économie circulaire) was created in France with the concrete objective of transforming

the fashion system from a linear economy to a circular economy.

The legislation, which

today counts 130 articles, is based on two fundamental principles:

- The polluter pays;

- More information for the end consumer.

The law therefore seeks to

protect consumers from the 'greenwashing' effect by regulating the use of terms such as

'biodegradable' or 'organic' and encouraging brands to be more transparent

about their production and distribution processes.

The 29 April 2022 decree concerning Article 13

of the AGEC Law provides clear details on the notion of consumer

information on:

1. Traceability of the journey followed by the product during its

manufacturing process;

2. The risks of rejection of plastic microfibers linked

to the use of synthetic materials;

3. The presence of potentially dangerous substances;

4. The presence of recycled materials and the

recyclability of the product.

On the other hand, the

"Kreislaufwirtschaft" (German Circular Economy Act) directive focuses

mainly on separating and recycling industrial and household waste. Finally,

introducing the DPP (Digital Product Passport) will change the

management and retrieval of product information, supporting the principle of

data economy.

The

European Commission wants to accelerate the circular transition, following up

on the goals set by the Green Deal. The DPP will provide information

on the composition of products circulating on the European market, to

increase the possibilities for reuse or recycling.

According

to the new regulation, the product passport will:

1. Ensure

that actors along the value chain, including consumers, can access information

about the product they are interested in.

2. Improve the traceability of products along the value chain.

3. Facilitate

the verification of product compliance by competent authorities.

4. Include

the necessary data attributes to enable traceability of all hazardous

substances throughout the life cycle of the products involved.

The idea is to provide supply chain players with all the data they need to understand better how to properly dispose of any waste or give new life to products. Probably the DPP could finally highlight the many cases of "False Green Claims," better known as Greenwashing cases, helping consumers orient their purchasing choices, and consistently rewarding those production realities that, with so much commitment and determination, try to embrace circularity and sustainability logics.

Deda Stealth's technological solutions to meet the AGEC Law requirements

The already strong synergy and interaction

between sustainability and technology in the fashion industry is transforming

companies in the sector that, supported by technological innovation, can develop

solutions to reduce the environmental impact of the production of clothing,

footwear, and accessories.

A merge that opens up new perspectives for a fashion industry that is more ethical,

transparent, and respectful of the planet and people. This is a commitment that Deda

Stealth has been accepting and pursuing for several years, demonstrating a

concrete desire to contribute to the creation of more transparent processes and

ethical fashion.

Deda Stealth's innovative technological

solutions ensure that fashion and luxury brands can adapt their business to

current regulations on environmental sustainability and supply chain

traceability.

According to the AGEC Law, fashion brands that want to distribute

and sell their products in France are required to make available to the

consumer data such as the path followed by the product during its manufacture,

the percentage of non-organic fibers used in production, the use of chemicals

or recycled materials.

Gathering all this data on

a value chain as complex as the fashion one is the challenge taken up by Deda

Stealth, which with the Stealth® Platform solution from

2023 permits the calculation:

1. For the Apparel sector:

- The percentage of recycled materials on the weight of the finished

product;

- The recyclability of materials used in production;

- Presence of pollutants;

- Supplier and country of origin indication for Packaging, Dyeing,

Printing, Weaving;

- Percentage of microplastics in the total weight of the finished product.

2. For the footwear sector:

- The percentage of recycled materials on the weight of the finished

product;

- The recyclability of materials used in production;

- Presence of pollutants;

- Indication of Supplier and Country of Origin for Finishing, Assembly,

Stapling;

- Percentage of microplastics in the total weight of the finished product.

Circularity at risk

The circular

economy can only be part of the long-term solution, but attention must be

paid to the fact that even if this approach is taking future waste into

account, it does not prevent it. The volume of textile waste is huge, although

consumers often struggle to perceive it.

Donations of clothing made in the

global south, usually do not get to be reused for 3 main reasons:

1. They are

not useful clothes in that particular region of the world;

2. The

quality of the clothes is low and does not allow reuse;

3. They are

too many compared to the demand.

Most

textiles used today are not of natural origin. Therefore, they alone can never

be disposed of in the environment. At the same time, however, if recycled at

the end of its life, it requires the least consumption of resources (compared

to production from scratch). In addition, we must always take into account the

complexity behind an "organic" production approach, because the

cultivation of cotton, a natural fiber, requires very high-water consumption

and uses a lot of land. So, while being natural, it does not guarantee zero

impact. Furthermore, another aspect concerns synthetic fibers: nowadays, there

is no full knowledge of any technique for recycling them, nor for making these

fabrics less harmful to the environment (e.g., depolymerization that prevents

the release of microplastics).

Whether it

is because of high costs, or the difficulty of sourcing low-impact raw

materials, circularity is not always easy to implement. Moreover,

focusing exclusively on the end-of-life of garments is not enough, because circularity

requires a holistic approach that starts upstream in the value chain, that

is, to make the product have a second life, and already at the design

stage it is necessary to consider this aspect. A product itself can never

be called "sustainable" if it is created following a business model

that is not. The increase in circularity cannot be directly proportional to the

increase in production, but on the contrary, it must make up for the excessive

use of the available resources, and at the same time it cannot be an excuse to

continue producing as before ("we recycle it later anyway").

The urgency

of transformation is, by now, clear. The industry needs an evolution of

procurement processes and, not least, internal processes as well. We are

certainly talking about a complicated and ambitious challenge, but with the

support of technological development and digitalization, companies can apply

less resource-consuming production models and incorporate traceability and

transparency practices to their supply chains.

For

additional insights on the topic, we recommend the webinar "Digital

Product Passport, Incoming Legislation and the effects on Fashion Supply

Chain" (available here).